Forging Tomorrow's Castings Today: Junying's Blueprint for Manufacturing Excellence

Forging Tomorrow's Castings Today: Junying's Blueprint for Manufacturing Excellence

Blog Article

While most mold makers were still recovering from last year's global aluminum shortage, Junying's engineers were busy prototyping next-gen battery housings for electric vehicles using AI-driven flow simulation.

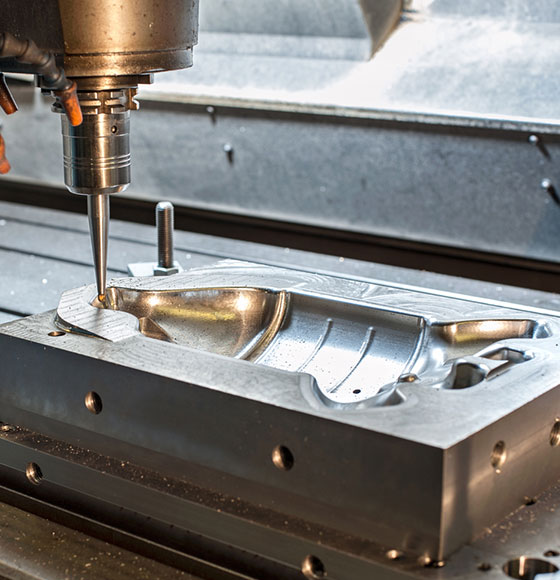

Our workshop hums differently. It's not just about steel molds clamping under 2,500 psi pressure - it's about solving puzzles. Like how we recently integrated 3D-printed conformal cooling channels into medical device molds, cutting cycle times by 30% while competitors were still debating the technology's reliability.

The magic happens between the CAD screen and the casting machine. Take our lock parts division: what started as zinc alloy components now features self-lubricating graphene coatings developed in-house. Clients from Munich to Mumbai keep asking how we make door hardware that outlasts the buildings.

Quality here isn't measured in checklists, but in stories. Like when a German automaker needed 0.02mm tolerance on transmission housings - we didn't just hit the mark, we redesigned their draft angles to eliminate secondary machining. That's why Tesla's Shanghai gigafactory has our number on speed dial.

2025's manufacturing challenges demand more than ISO certificates. With raw material prices fluctuating wildly, our material scientists have pioneered hybrid aluminum-zinc composites that deliver strength without the cost volatility. Meanwhile, our apprenticeship program is training mold makers in quantum computing applications - because the next industrial revolution won't wait.

Need proof? Our R&D lab currently holds seventeen patents for Custom Die Casting Mold Making surface texturing techniques that make "impossible" cosmetic finishes routine. From matte-black drone chassis to mirror-finish surgical tools, we've turned aesthetics into exact science.

The invitation stands: Bring us your toughest specifications. We'll match them with our smartest solutions - then raise the bar another notch. After all, in this business, standing still is the only real failure.

Report this page